Drilling Deep: Innovations in Machining Techniques and Tools

Drilling Deep: Innovations in Machining Techniques and Tools

In the realm of manufacturing and metalworking, precision and innovation are paramount. The evolution of machining techniques and tools has revolutionized how we fabricate components, pushing boundaries and enhancing efficiency. Let's delve into the world of machining and uncover the latest innovations that are shaping the industry.

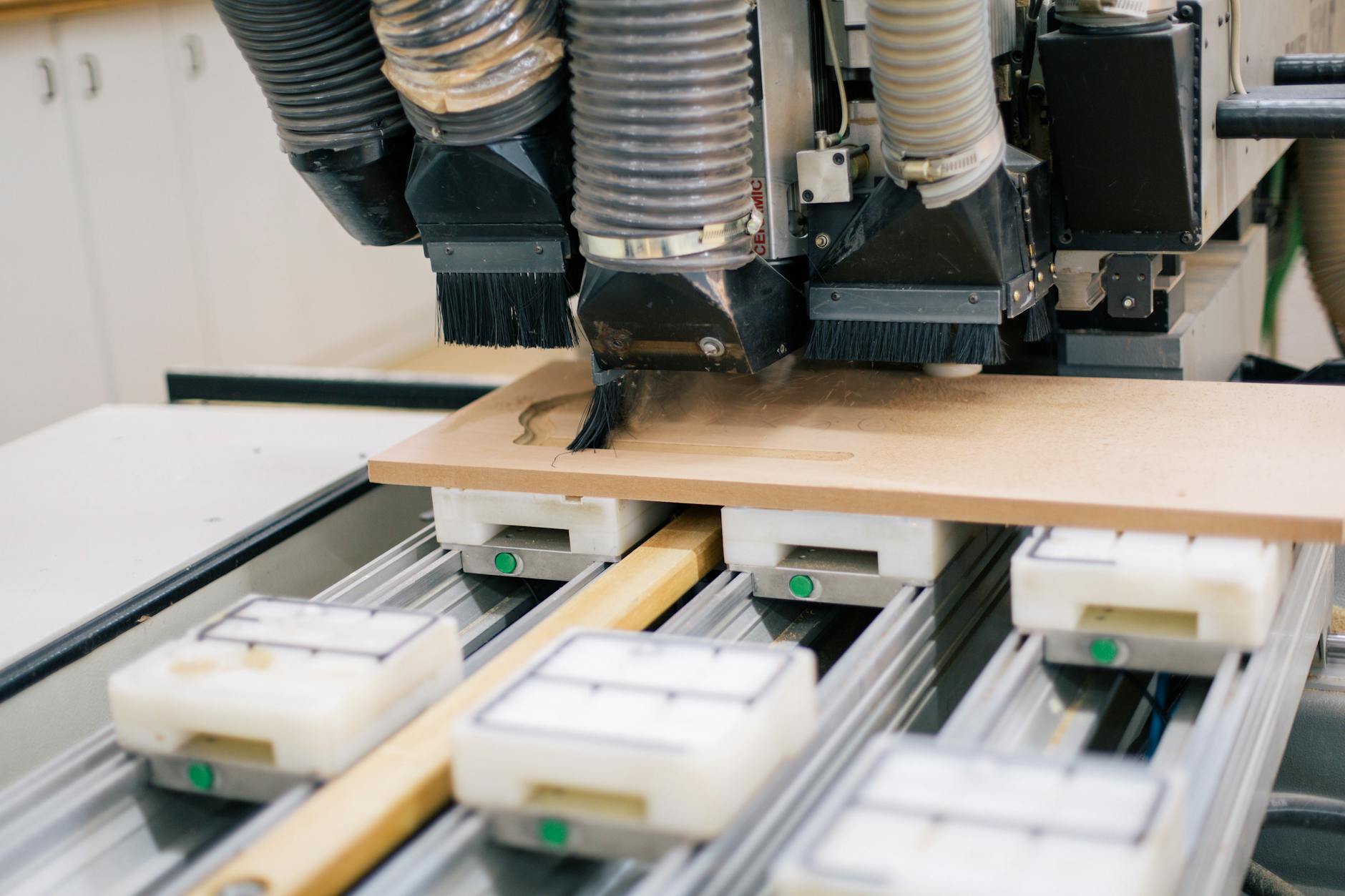

Machining centers serve as the beating heart of any manufacturing facility, orchestrating a symphony of movements to craft workpieces with finesse. These centers integrate various tools like drill presses and turning machines to streamline production processes. With advanced capabilities for prototyping and fabrication, machining centers pave the way for rapid iteration and optimization, catapulting industries into the future.

As we reflect on the innovations in machining techniques and tools, it becomes evident that the landscape of metalworking is everevolving. From CNC machining to advanced fabrication methods, the future holds limitless potential for creativity and efficiency. By embracing these innovations and staying at the forefront of technological advancements, manufacturers can carve a path towards unprecedented success and growth.