Turning the Tables: Elevating Machining Center Efficiency

Elevating Machining Center Efficiency

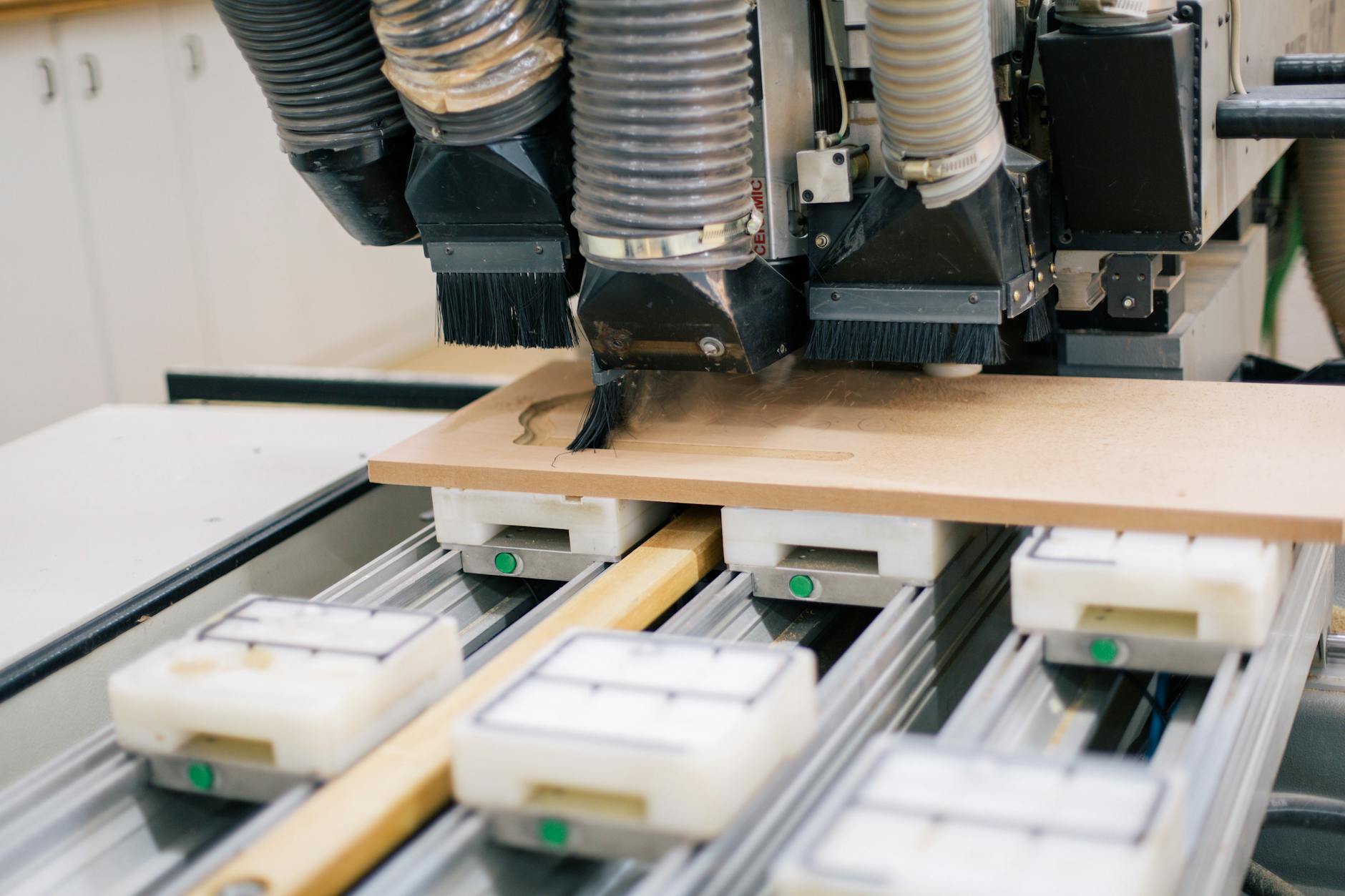

In the world of __CNC machining__ and __metalworking__, efficiency is the name of the game. Every __machinist__ knows that time is money, and maximizing productivity is crucial to staying ahead in the competitive landscape of __fabrication__ and prototyping.

One of the key challenges in __machining__ is achieving the desired __tolerance__ levels on the finished parts. With advancements in technology and the advent of sophisticated CNC machines, maintaining tight tolerances has become more achievable than ever before.

In the everevolving world of __metalworking__ and __fabrication__, the pursuit of efficiency remains a constant goal. By leveraging the power of precision tools, optimizing workpiece tolerance, and implementing smart shop floor strategies, machinists can elevate their machining center efficiency to new heights.

Have you ever wondered how a drill press differs from a milling machine in terms of functionality?

Why is CNC machining considered a gamechanger in the world of metalworking?

What are some common challenges faced by machinists when working on intricate prototypes?

How can automation technologies revolutionize the efficiency of a machining center?

What role does continuous training and upskilling play in enhancing the capabilities of a modern machinist?

Tags: